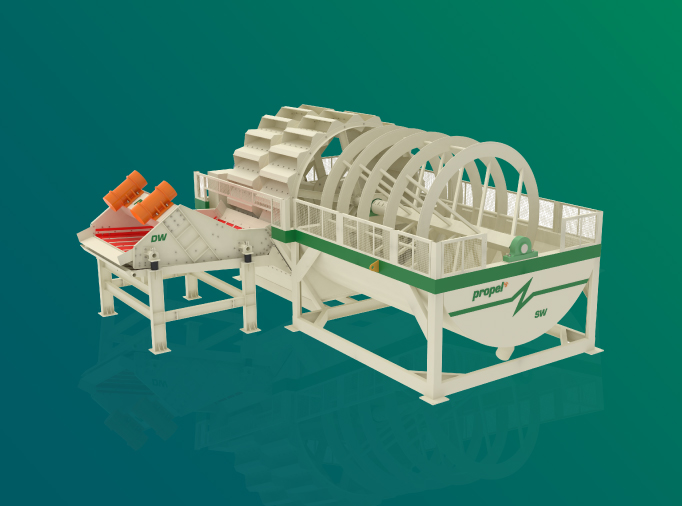

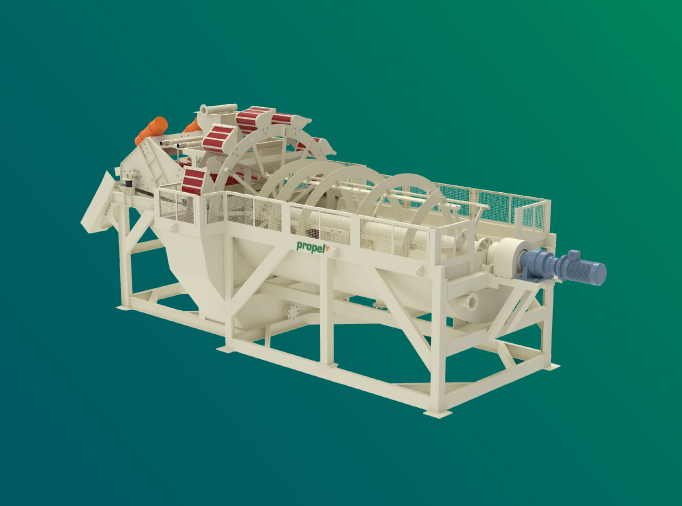

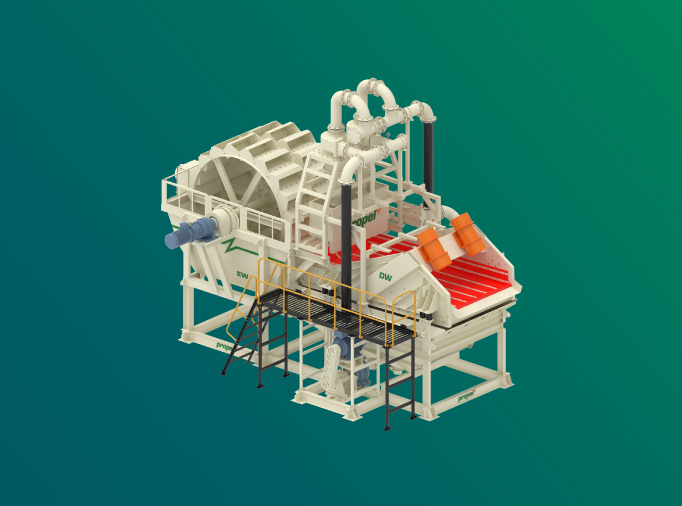

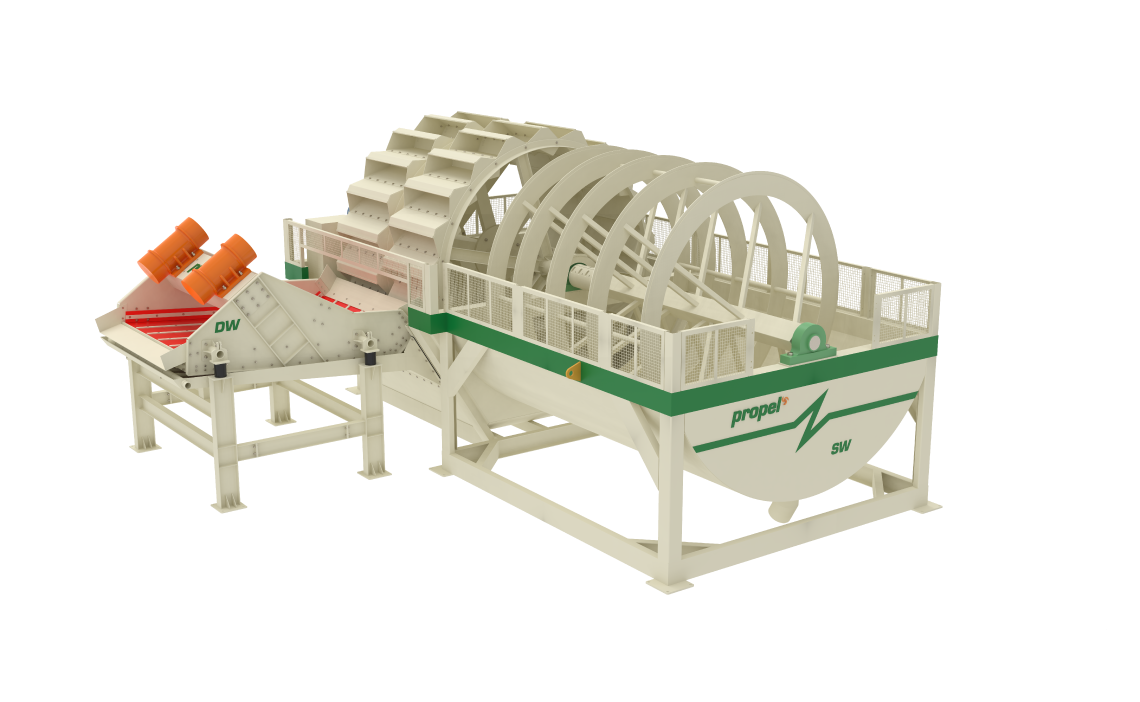

SAND WASHER

SW SERIES

Bucket type sand washing equipment can improve the sand quality. Propel Sand Washers adopt advanced technology for high efficiency sand washing.

WATCH VIDEO

TECHNICAL DATA

| SERIES | UNITS | SW 75 | SW 100 | SW 150 | SW 200 |

|---|---|---|---|---|---|

| *Capacity | TPH | 45 - 60 | 60 - 80 | 90 - 120 | 120 - 160 |

| Wheel diameter | m | 2.27 | 2.5 | 2.75 | 3.1 |

| Number of buckets | m/sec | 34 | 36 | 42 | 42 |

| Screw Diameter |

mm (inch) |

1800 (71.0) |

1700 (67.0) |

2200 (86.6) |

2800 (110.2) |

| Water Tank Capacity | ltrs | 4500 | 5000 | 6000 | 8000 |

| Motor Power |

kW (hp) |

5.5 (7) |

7.5 (10) |

9.3 (12) |

9.3 (12) |

| Weight |

kg (Ton) |

3600 (3.6) |

5200 (5.2) |

7100 (7.1) |

8500 (8.5) |

| DEWATERING SCREEN | |||||

| SERIES | UNITS | SDW 75 | SDW 100 | SDW 150 | SDW 200 |

| Screen Area (Wx L) | mm (Inch) |

900 x 1800 (35.4 x 71.0) |

1200 x 2150 (47.2 x 84.6) |

1500 x 2500 (59.1 x 98.4) |

1800 x 2500 (71.0 x 98.4) |

| *Capacity | TPH | 45 - 60 | 60 - 80 | 90 - 120 | 120 - 160 |

| Operating Angle | deg | 5° | 5° | 5° | 5° |

| Motor Power |

kW (hp) |

2 x 1.13 (2 x 2) |

2 x 1.5 (2 x 2) |

2 x 2.2 (2 x 3 ) |

2 x 3.2 (2 x 4) |

| Weight |

Kg (Ton) |

775 (0.77) |

850 (0.85) |

1300 (1.3) |

1900 (1.9) |

*Details may vary based on application

Note: All the above technical details may vary at any time during engineering process & design development