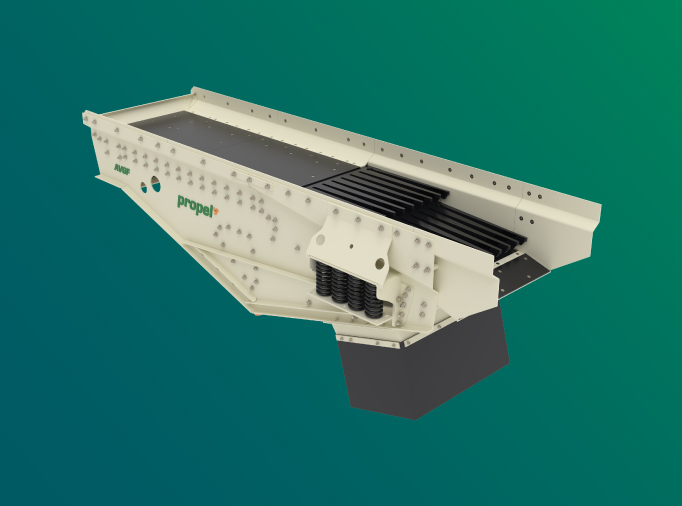

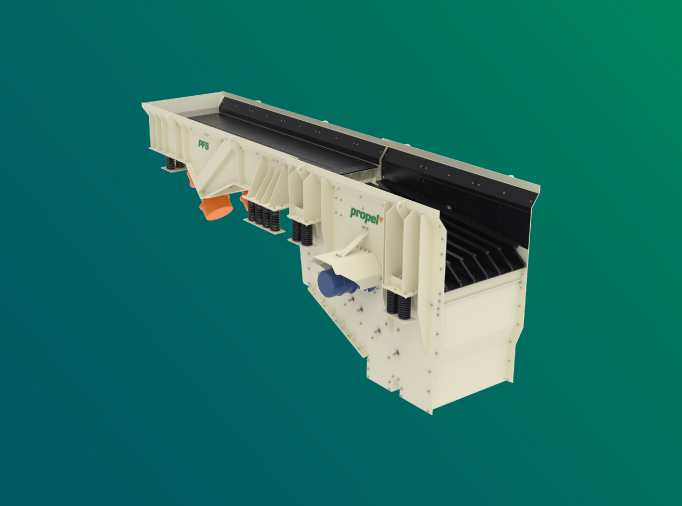

GRIZZLY FEEDER

AVGF SERIES

The Propel Grizzly Feeder can handle large feed rates with coarse blasted rock and also the material impact from dump trucks or wheel loaders. Its step height and tapered grizzly bars eliminate pegging and enhances the efficiency of separation.

TECHNICAL DATA

| DESCRIPTION | UNIT | AVGF 940 V2 | AVGF 1142 V2 | AVGF 1344 V2 | AVGF 1353 V2 | AVGF 1661 V2 |

|---|---|---|---|---|---|---|

| Dimension (W x L) | mm | 900 x 4000 | 1100 x 4200 | 1300 x 4400 | 1300 x 5300 | 1600 x 6100 |

| (inch) | (35.4 x 157.5) | (43.3 x 165.4) | (51.2 x 173.2) | (51.2 x 208.7) | (63.0 x 240.2) | |

| Feed Size (Max.) | mm | 450 | 700 | 900 | 900 | 1200 |

| (inch) | (17.7) | (27.6) | (35.4) | (35.4) | (47.2) | |

| *Capacity (Max.) | TPH | 250 | 400 | 500 | 600 | 1000 |

| Grizzly Area (W x L) | mm | 900 x 1200 | 1100 x 1500 | 1260 x 1400 | 1260 x 2100 | 1600 x 2600 |

| (inch) | (35.4 x 47.2) | (39.4 x 59.1) | (49.6 x 55.1) | (49.6 x 82.7) | (63.0 x 102.4) | |

| Scalp Screening Area (W x L) | mm | 840 x 740 | 1000 x 1000 | 1200 x 900 | 1260 x 1800 | 1628 x 2100 |

| (inch) | (33 x 29.1 ) | (39.4 x 39.4) | (47.2 x 35.4) | (49.6 x 70.9) | (64.1x 82.7) | |

| Grizzly Bar Material | Replaceable wear resistant material prevents clogging and packing | |||||

| Mounting Type (optional) | Skid | |||||

| Vibrating Unit | Electrical unbalanced motors | Modular Vibrator | ||||

| Motor Power | kW | 2 x 4.3 | 2 x 4.3 | 2 x 6.2 | 2 x 7.99 | 1 x 30 |

| (hp) | (2 x 5.76) | (2 x 5.76) | (2 x 8.3) | (2 x 10.71) | (1 x 40) | |

| Weight | kg | 3350 | 3500 | 4800 | 6100 | 10800 |

| (Ton) | (3.35) | (3.5) | (4.8) | 6.1 | 10.8 | |

*Details may vary based on application

Note: All the above technical details may vary at any time during engineering process & design development