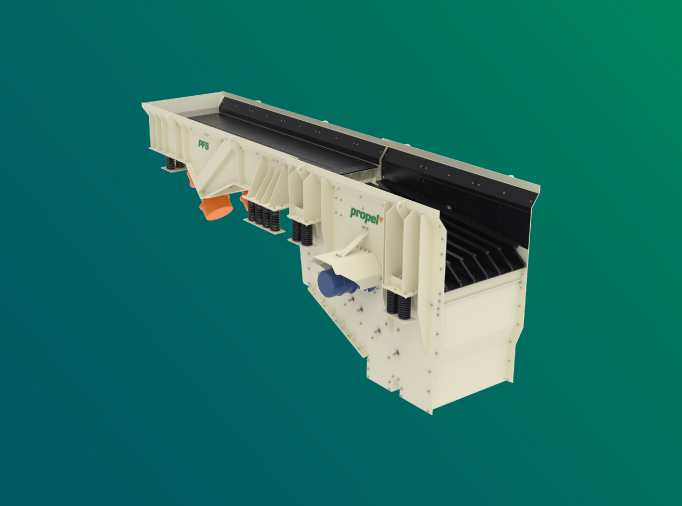

FEEDER SCREEN

PFS SERIES

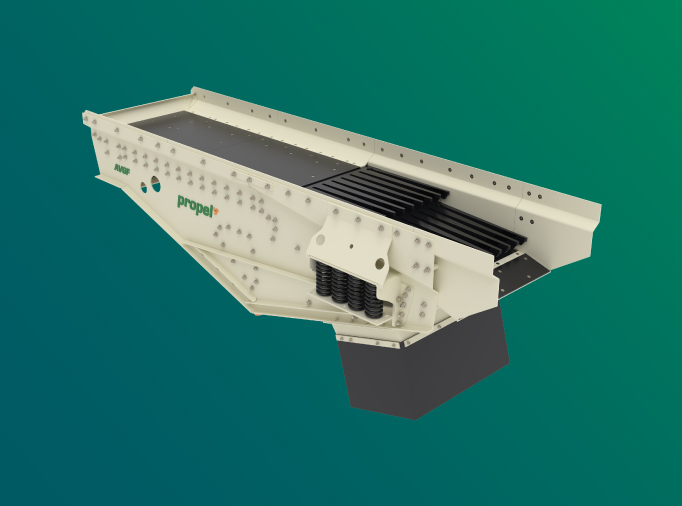

Propel Primary Feeder Screens are a combination of a separate feeder and separate Grizzly Screen. Primary Feeder Screen can significantly improve the total throughput of a primary station by its ability to keep a primary crusher fully fed even during varying feed conditions. Propel Feeder Screen is equipped with counter unbalanced electric motor drive for good reliability and gives stepless feed rate adjustments. Suitable for horizontal and inclined operating conditions.

TECHNICAL DATA

| DESCRIPTION | UNIT | PFS 955 | PFS 1161 | PFS 1365 | PFS 1680 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Feeder Screen | AVF 930 V2 | AVGS 925 V2 | AVF 1136 V2 | AVGS 1125 V2 | AVF 1340 V2 | AVGS 1325 V2 | AVF 1650 V2 | AVGS 1630 V2 | |

| Dimensions (W x L) | mm | 900 x 3100 | 980 X 2500 | 1040 X 3600 | 1150 X 2500 | 1250 X 3950 | 1350 X 2500 | 1630 X 5000 | 1760 X 2900 |

| (inch) | (35.4 x 122.0) | (38.6 x 98.4) | (40.9 x 141.7) | (45.3 x 98.4) | (49.2 x 155.5) | (53.1 x 98.4) | (64.1 x 196.8) | (69.3 x 114.1) | |

| Feed Size (Max.) | mm | 560 | 560 | 750 | 750 | 900 | 900 | 1200 | 1200 |

| (inch) | (22.0) | (22.0) | (29.5) | (29.5) | (35.4) | (35.4) | (47.2) | (47.2) | |

| *Capacity (Max.) | TPH | 250 | 250 | 400 | 400 | 500 | 500 | 900 | 900 |

| Grizzly Area (W x L) | mm | - | 980 x 2300 | - | 1150 x 2300 | - | 1350 x 2340 | - | 1750 x 2700 |

| (inch) | - | (38.6 x 90.55) | - | (45.3 x 90.6) | - | (53.1 x 92.1) | - | (68.9 x 106.2) | |

| Scalp Screening Area (W x L) | mm | - | 1000 x 1640 | - | 1150 x 1640 | - | 1360 x 1680 | - | 1772 x 1950 |

| (inch) | - | (39.3 x 64.6) | - | (45.3 x 64.6) | - | (53.5 x 66.1) | - | (69.8 x 76.8) | |

| Grizzly Bar Material | Replaceable wear resistant material prevents clogging and packing | ||||||||

| Mounting Type (Optional) | Skid | ||||||||

| Drive Mechanism | Electric unbalanced motors | ||||||||

| Motor Power | kW | 2 x 4.3 | 2 x 3.6 | 2 x 4.3 | 2 x 5.8 | 2 x 4.3 | 2 x 6.4 | 2 x 7.99 | 2 x 7.99 |

| (hp) | (2 x 5.76) | (2 x 4.82) | (2 x 5.76) | (2 x 7.7) | (2 x 5.76) | (2 x 8.5) | (2 x 10.71) | (2 x 10.71) | |

| Hopper Volume (Max.) | m³ | 25 | 25 | 32 | 32 | 45 | 45 | 60 | 60 |

| **Weight | kg | 2300 | 3100 | 2800 | 3400 | 3900 | 4500 | 5800 | 6200 |

| (Ton) | 2.3 | 3.1 | 2.8 | 3.4 | 3.9 | 4.5 | 5.8 | 6.2 | |

*Details may vary based on application

**Weight inclusive of motor & accessories

Note: All the above technical details may vary at any time during engineering process & design development