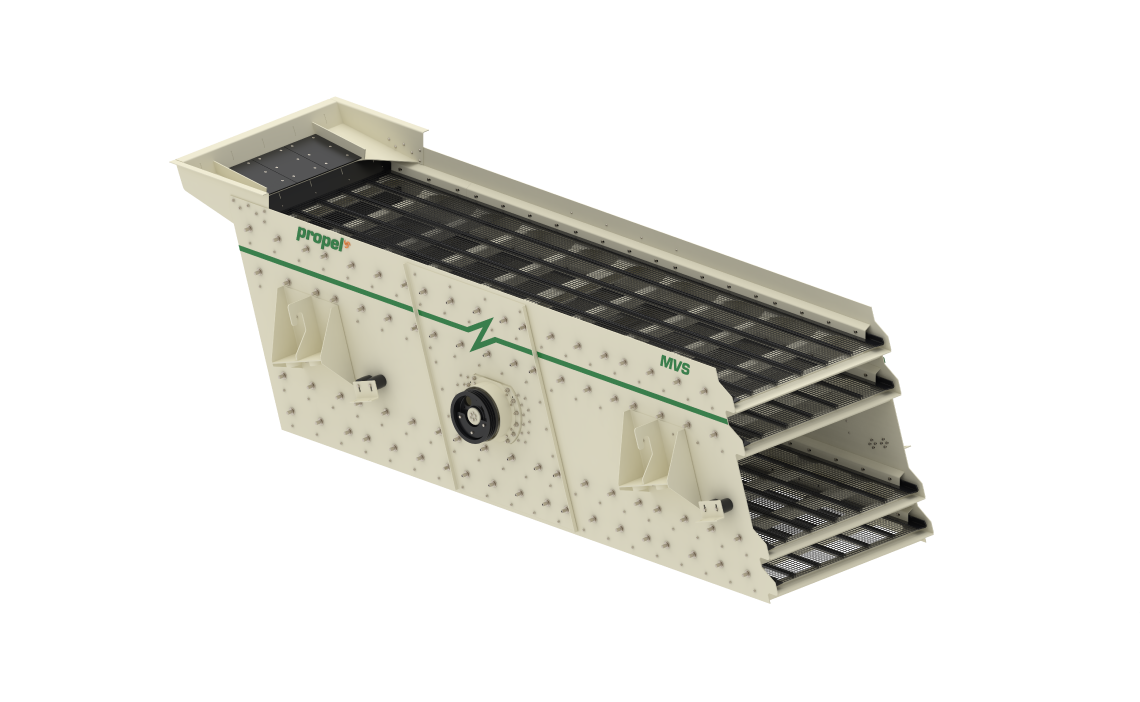

VIBRATING SCREEN

MVS SERIES

Propel MVS screens are versatile. They can be used for primary, secondary and tertiary screening. MVS screen standard slope angle is 18 ° but can be modified for special applications. It can be used for wet screening fitted with spray pipes.

WATCH VIDEO

TECHNICAL DATA

| SERIES | UNITS | MVS 1540 | MVS 1845 | Dual Slope 1860 | MVS 2060 | MVS 2561 | MVS 1850 |

|---|---|---|---|---|---|---|---|

|

Screen Size (W x L) |

mm (inch) |

1500 x 4000 (59.1 x 157.5) |

1800 x 4500 (71.0 x 177.2) |

1850 x 6000 (72.9 x 236.2) |

2000 x 6000 (78.7 x 236.2) |

2500 x 6100 (98.4 x 240.2) |

1800 x 5000 (70.9 x 196.9) |

| Screening Area | sq.m | 6.0 | 8.1 | 11.1 | 12.0 | 15.1 | 8.91 |

| *Capacity | TPH | 300 | 400 | 600 | 650 | 800 | 200 |

| Number of Decks | 2 / 3 / 4 | 2 / 3 / 4 | 4 | 2 / 3 / 4 | 3 / 4 | 1 | |

| Mounting Type (optional) | Skid | Skid | Skid | Skid | Skid | Skid | |

| Screen Position | Inclined | Inclined | Inclined | Inclined | Inclined | Inclined | |

| Type of Motion | Circular | Circular | Elliptical | Circular | Circular | Circular | |

| Motor Power |

kW (hp) |

15 (20) |

15 (20) |

15 (20) |

22 (30) |

30 (40) |

2X5 (6.7) |

| Weight |

kg (Ton) |

3500 / 4300 / 5100 (3.5 /4.3 / 5.1) |

4000 / 4800 / 5400 (4.0/ 4.8 / 5.4) |

7600 (7.6) |

6600 / 7500 / 8700 (6.6/ 7.5 / 8.7) |

12500 / 14500 (12.5 / 14.5) |

4000 (4.0) |

*Details may vary based on application

**Motor Power for MVS 1540 single deck

Note: All the above technical details may vary at any time during engineering process & design development