How propel design team overcame very challenging site conditions

We started working with Alpha mining, Oman in the year 2020. The project is located in the Gabbro quarry area of Oman and it comes with its own challenges.

Alpha mining chose Propel over other brands because of

- Operation flexibility of Propel machines.

- Tailored application support to meet the production needs Design support for layout optimization in difficult terrain with limited area.

- Minimum civil and structural costs involved.

- Products from Propel provide value for money, while always retaining quality and performance.

We stand apart because

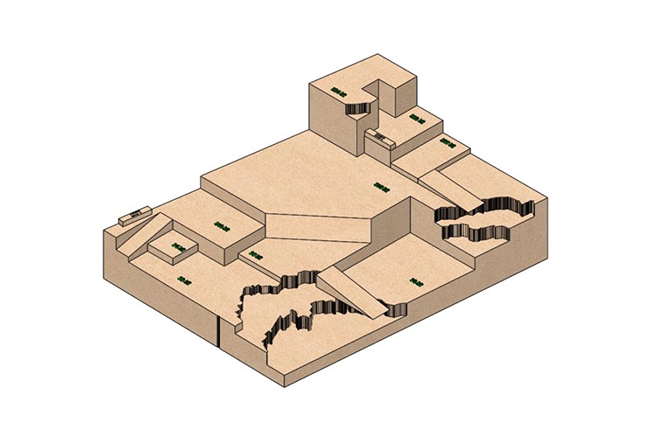

- Propel primary station with Jaw crusher AVJ 1214 has wider feed opening to take in large -sized boulders.

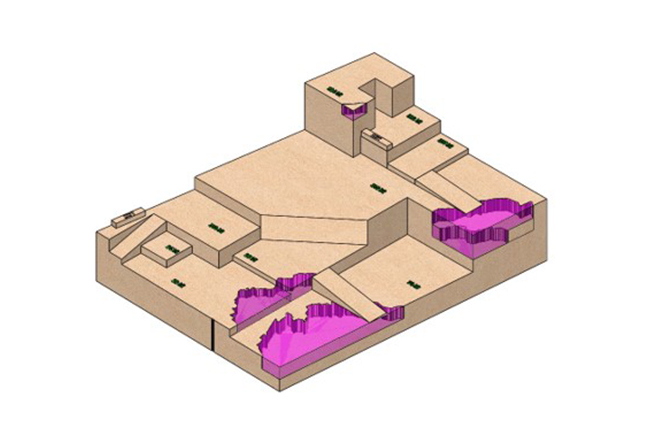

- Three secondary crushing stations with Cone AVC 250 after stockpile provides flexibility in operation and maintenance at site. What more, there is no need to stop the plant completely.

- Two tertiary stations with VSI-AVVI 250 has provisions to alter operational settings as per the changes in the product output characters.

HOW WE IMPRESSED ALPHA MINING, OMAN WITH OUR DESIGN PROWESS?

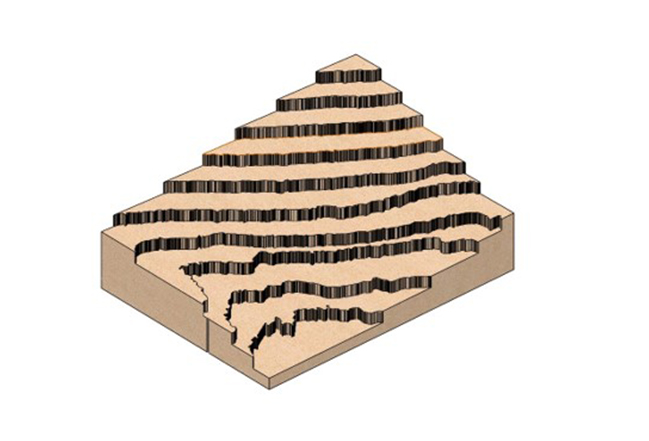

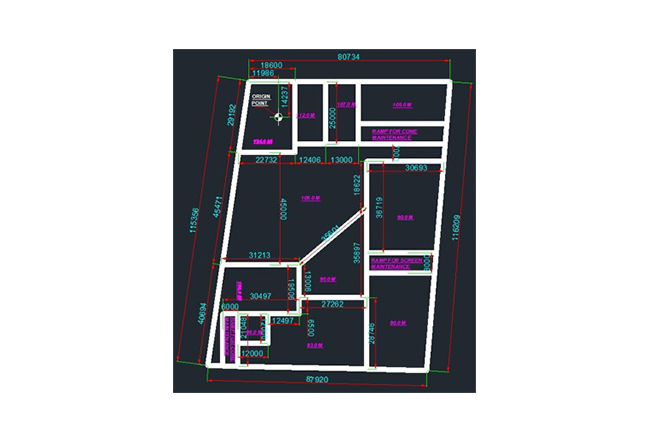

The site conditions were tough. It was indeed very challenging for our engineers to finalise the optimum design as per the customer's requirements. We had to make different level of benches on the mountain to place the machine to aid plant operation.

We positioned the stockpile in such a way that it had larger storage capacity with minimum conveyor length possible. This way, we turned the challenge of height difference into benefit for the customer.

The supporting structures and chutes were custom designed to suit the needs of the project. The product output has been positioned in such a way that it gives more storage volume and also ensures no disturbance in the internal plant movement and operation.

We have planned the application and layout in such a way that it provides the customer, the space and options to expand the plant, if needed.