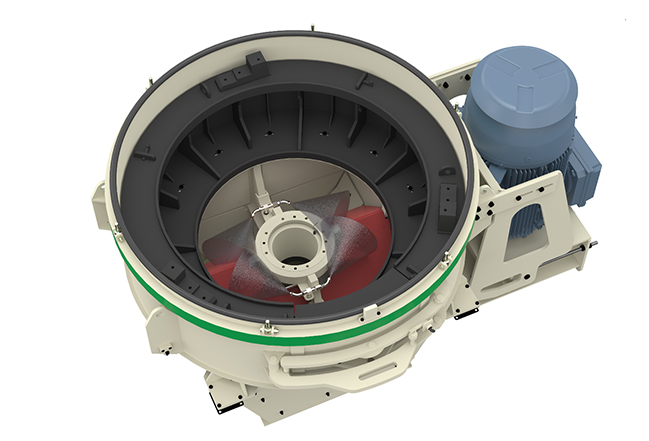

Handling wet material at Vertical Shaft Impactor

Propel Vertical Shaft Impactor has been developed with inputs from aggregate producers. It enhances the shape of the aggregates and improves the surface structure. It is suitable for all types of materials.

PROPEL VSI has the ability to handle hard, abrasive, fine, moist or sticky feed materials.

THE CHALLENGE

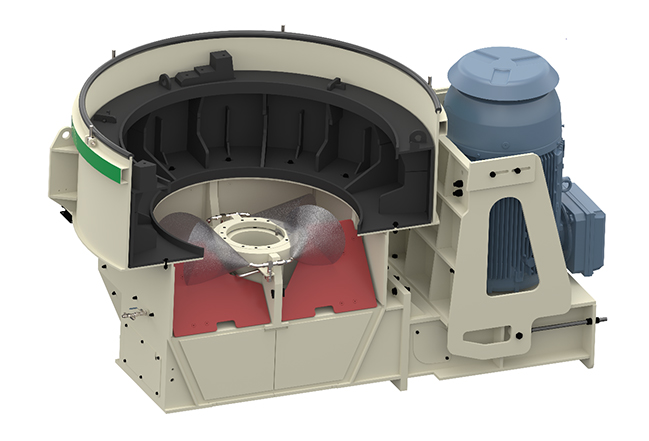

In a crushing plant, the major concernfor the aggregate producer is the wet material. The wet material processing in VSI during rainy season and recirculating material from washing screen causes accumulation of material in the crushing chamber as well as in the crusher base. Stagnation of material causes jamming of rotor and ends up in drawing higher current and thus electric motor tripping.

THE PROPEL SOLUTION

To overcome this challenge, we have introduced new features in our vertical shaft impactor as narrated below.

A water spray kit system at crusher base (non-stick plates +water sprinkler system) has been introduced at the crushing zone exit area which will ensure smooth continuous movement of crushed wet materials.

Introduction of water spray kit system with regulated flow rate at designated pressure ensures its optimum mixing of water with the output aggregate. This eliminates too much of water at discharge conveyor causing spillage of material with water.

PROPEL VSI nozzles perform well under high or low water pressures in the range of 0.5 to 3.0 bar g, having flow capacity range of 8 1pm to 16 1pm.

The nozzles give out a sharply defined cone-shaped efficient water jet spray. Ideal for dust control applications safeguarding environment. This system is very economical and is abrasion/ corrosion resistant.

This feature has been implemented in all our VSI models. Suitable retrofit conversion kits are available for the machines supplied already running in field.