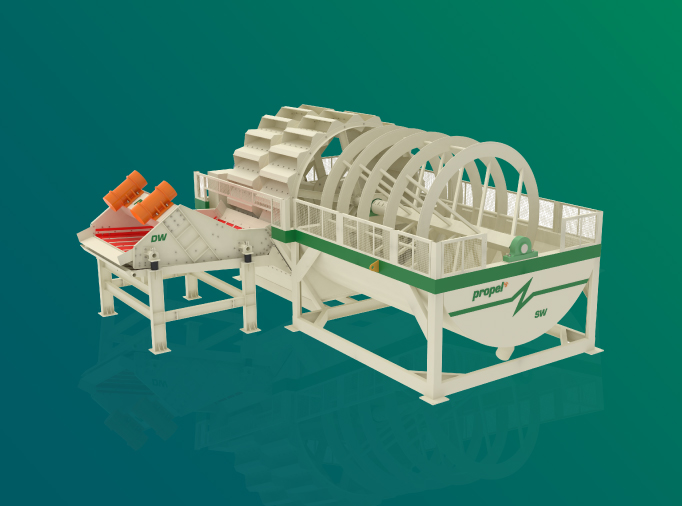

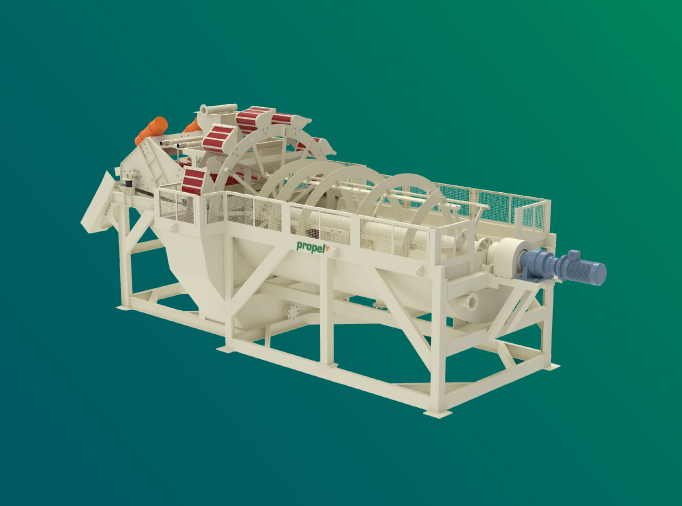

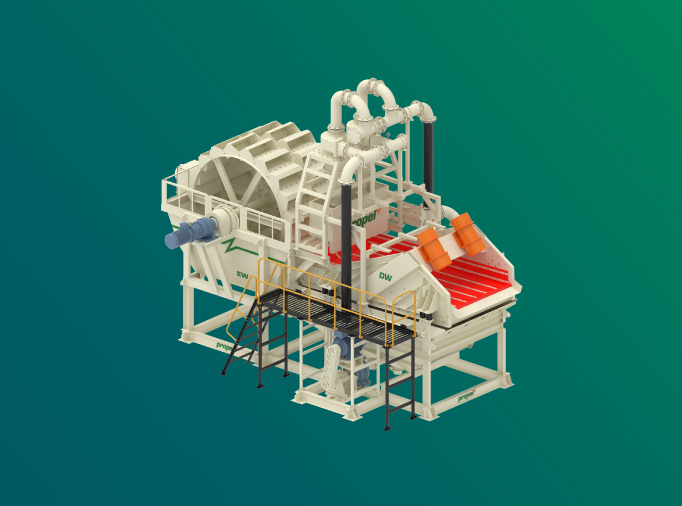

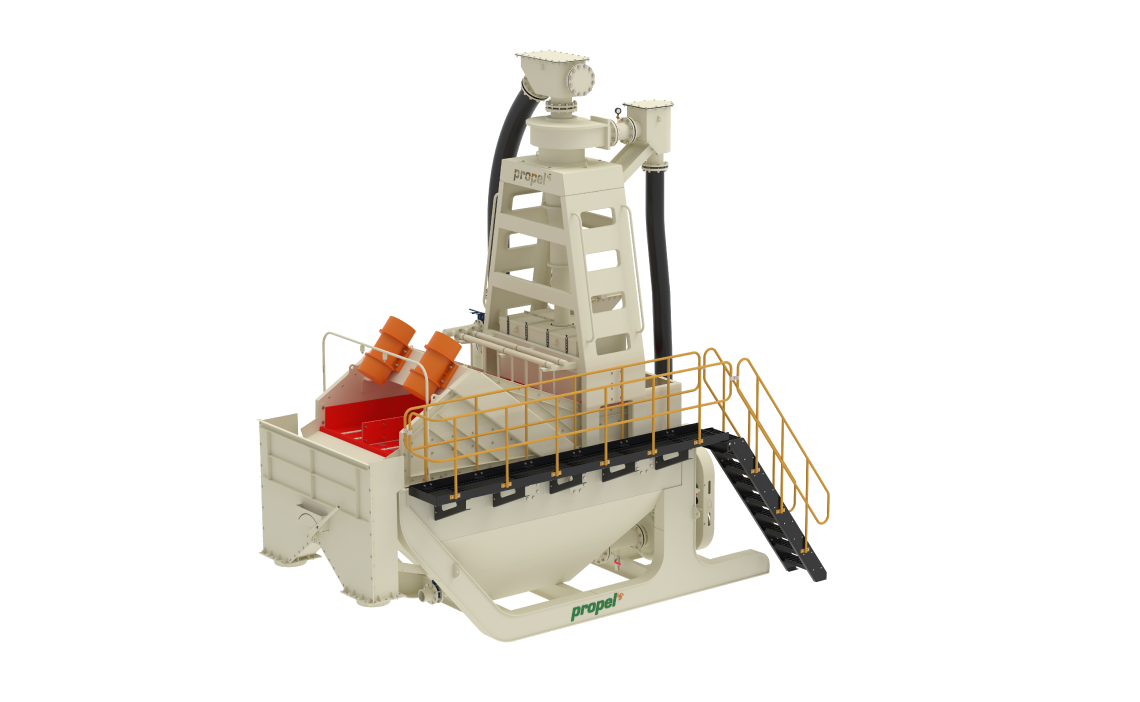

PRO WASH

PW SERIES

Propel Pro Wash series is designed to ensure maximum efficiency from the washing plant. It facilitates the extremely accurate separation of silts and clays from the final washed sand products (m-Sand & p-Sand). It is employed in the production of specialised sands.

WATCH VIDEO

TECHNICAL DATA

| DESCRIPTION | UNIT | PW 100 V2 | PW 150 V2 | PW 200 V2 | PW 250 V2 |

|---|---|---|---|---|---|

| *Capacity | TPH | 60 - 80 | 90 - 120 | 120 - 160 | 150 - 250 |

| Hydro Cyclone Size | mm | 400 | 400 | 500 | 500 |

| (inch) | (15.7) | (15.7) | (19.7) | (19.7) | |

| Slurry Pump Size (Suction x Delivery) |

mm | 152.4 x 101.6 | 203.2 x 152.4 | 203.2 x 152.4 | 203.2 x 152.4 |

| (inch) | (6.0 x 4.0) | (8.0 x 6.0) | (8.0 x 6.0) | (8.0 x 6.0) | |

| Slurry Pump Capacity | m³/hr | 130 | 222 | 278 | 370 |

| Slurry Pump Power | kW | 15 | 30 | 37 | 45 |

| (hp) | (20) | (40) | (50) | (60) | |

| Weight | kg | 8400 | 8800 | 11800 | 14000 |

| (Ton) | (8.4) | (8.8) | (11.8) | (14.0) | |

| DEWATERING SCREEN | |||||

| PDW 100 | PDW 150 | PDW 200 | PDW 250 | ||

| Screen Area (W x L) | mm | 1800 x 2800 | 1800 x 2800 | 1800 x 4000 | 2400 x 3850 |

| *Capacity | TPH | 60 - 120 | 90 - 120 | 120 - 160 | 150 - 250 |

| Operating Angle | deg | 0o to 2o | 0o to 2o | 0o to 2o | 0o to 2o |

| Motor Power | kW | 2 x 2.88 | 2 x 2.88 | 2 x 6.2 | 2 x 11 |

| (hp) | (2 x 4) | (2 x 4) | (2 x 8) | (2 x 15) | |

| Weight | kg | 2400 | 2400 | 3800 | 4900 |

| (Ton) | (2.4) | (2.4) | (3.8) | (4.9) | |

*Details may vary based on application

Note: All the above technical details may vary at any time during engineering process & design development